BioPACIFIC MIP Facilities

Access to the BioPACIFIC MIP facilities, instrumentation, and expert staff is free for users with approved proposals.* A complete list of major instrumentation can be found here.

For details on how to become a BioPACIFIC MIP User, click here.

*For the full Policies regarding access, click here.

Contact

Eleni Papananou

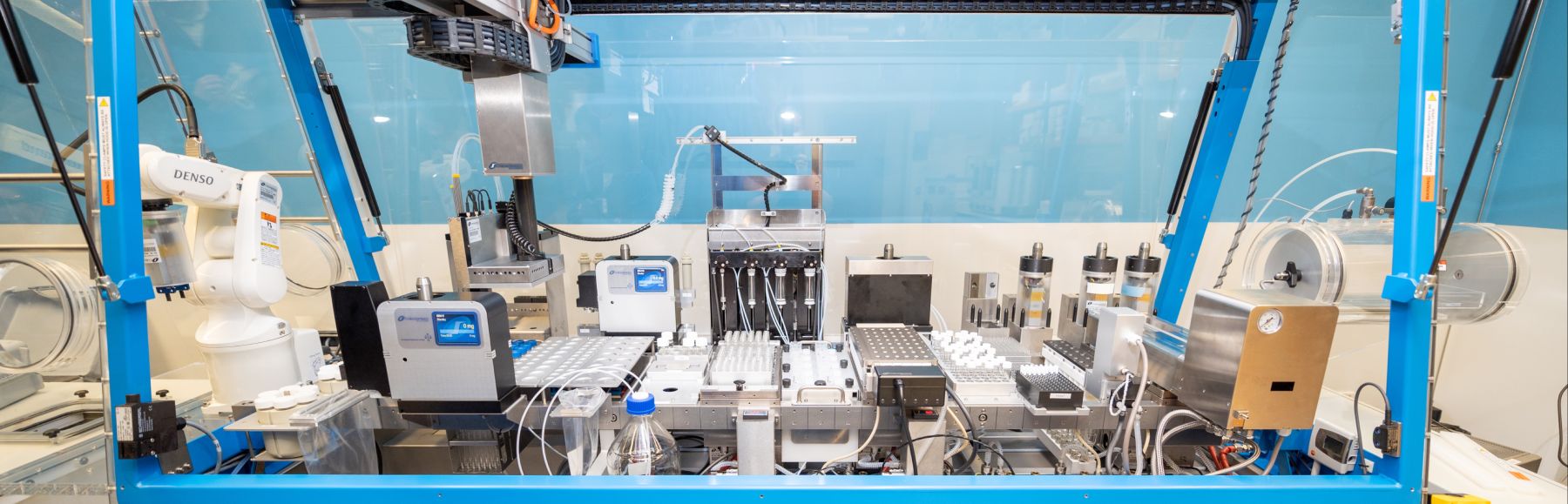

The BioPACIFIC MIP Living Biofoundry Facility (LBF) works with users to accelerate discovery and scale-up production of bio-derived building blocks and biopolymers through automated synthetic biology and microbial engineering. The facility is developing high-throughput methods for gene assembly, amplification, transformation, strain growth, and metabolite analysis as well as preparing to support mineable data library of biosynthetic pathways for the production of unique bio-derived monomers.

- Capabilities and Unique Aspects

-

The Thermo Fisher Laboratory Automation System (LAS) provides the core platform for the facility that allows high throughput automation of synthetic biology protocols. The LAS features a state-of-the-art Spinnaker microplate robot that integrates an automated tower incubator and shaker, plate sealers and peelers, PCR thermocyclers, plate fillers, barcode labeler, one-of-a-kind deep well plate washer, centrifuge, plate reader, and Tecan Fluent 780 liquid handler. Major upgrades to the Fluent 780 have added on-deck equipment including a microplate vacuum purification system, two heating/cooling/shaking modules, a plate reader with fluid injection, plate washer with magnetic bead purification and an Alpaqua magnetic bead purification unit.

Workflows that have been developed include polymerase chain reaction (PCR) DNA amplification, PCR product purification, gene refactoring and assembly, microbial transformation, purification of plasmid DNA, and cold solvent extraction of metabolites from cells for LC/MS sample preparation and high throughput enzyme kinetics assays with coacervates, all in 96-well microplate format. The LBF also offers a Thermo Fisher ultra-high-performance liquid chromatography and triple quad mass spectroscopy system for separation and quantification of molecules from biosynthetic pathways. Some of the equipment in the LBF can be used remotely in user projects.

The BioPACIFIC MIP Synthetic Chemistry Facility features a suite of unique instrumentation in a one-of-a-kind facility that forms the nexus between discovery, materials-by-design, and biomaterial production. This collection of instrumentation includes: (i) the Symphony X solid-phase synthesizer (Gyros Protein Technologies), (ii) the Nexera preparative HPLC (Shimadzu), (iii) the Nexera analytical HPLC (Shimadzu), (iv) the Swing XL automated chemistry platform (Chemspeed Technologies), (v) the R-series flow chemistry system (Vapourtec) with in-line FTIR (Mettler Toledo) and NMR (Magritek) analytics, (vi) a Selekt flash chromatography system (Biotage), (vii) a V-10 touch evaporator (Biotage), and (vii) a benchtop freeze dryer (Labconco).

- Capabilities and Unique Aspects

-

The Symphony X is a flexible, automated synthesizer that maximizes the production of novel peptides, peptoids, and other sequence specific materials derived from solid-phase synthesis. Scalability and high-throughput screening are enabled through the independent operation of multiple reaction vessels (RVs), capable of synthesizing 24 unique sequences simultaneously from up to 2 g resin. Challenging sequences are accessible using one specialized RV equipped with IR heating up to 90 °C and oscillation mixing capabilities. Additional features include the ability to perform single-shot deliveries of precious or scarce reagents with no waste, as well as the automated on-board cleavage of 12 sequence-specific materials directly from the RVs with no user intervention.

The BioPACIFIC MIP Chemspeed Swing XL automated chemistry platform enables deployment of automated workflows at the benchtop scale. Its modular configuration combines robotics with multiple reactor systems to execute common laboratory procedures, including parallel synthesis, reaction discovery, reaction optimization, and time course studies. Equipped with mountable tool-heads for solid and (viscous) liquid handling, a single robotic arm translocates reagents among the available photochemical, high-pressure, and double-jacket cooled reactor arrays, which can control temperatures (–20–180 °C) under inert or pressurized environments up to 100 bar. Work-up tasks are supported with additional (robotic) modules for solvent evaporation, vacuum filtration, solid-phase extraction, and centrifugation.

Automated flow systems potentially enable scalability with safer protocols and higher product yields than those in batch. BioPACIFIC MIP offers a Vapourtec R-series flow chemistry system as a uniquely user-friendly tool with the utmost chemical flexibility. High temperature, electrochemical, photochemical, and sub-ambient reactors can be coupled for sequential transformations or operated alone. For photomediated processes, interchangeable mercury lamp and LED based light sources modulate the wavelength of light with precision over the range of 220 to 700 nm. Additionally, reaction optimization and screening studies can employ in-line FT-IR (Metter Toledo) or NMR (Magritek) analysis.

For the purification of peptoids, peptides, and other biomaterials, BioPACIFIC MIP supports both preparative and analytical workflows using high-performance liquid chromatography (HPLC), each with dedicated UV-vis detectors and MS capabilities. The HPLC’s semi-preparative (19 mm ID) C-18 columns have been upgraded to two 50 mm ID preparative columns with 100 and 300 Å pores, respectively, to increase peptide/peptoid mass load and purification throughput. Purification of biopolymers and their small molecules precursors is supported through a Selekt automated flash chromatography system (Biotage) that enables the separation of unknown mixtures using optimized pre-packed columns on a preparative or semi-preparative scale. Moreover, auxiliary UV and evaporative light-scattering detectors streamline fraction collection, saving time and reducing solvent consumption. In addition, an automated evaporator system, the V-10 touch (Biotage), rapidly dries down a sequential queue of collected fractions or high-boiling solvents from synthesis to greatly simplify and improve work-up efficiency. To increase shelf- and transit-stability of synthesized materials, BioPACIFIC MIP offers a 4.5 L (–84 °C) FreeZone Benchtop Freeze Dryer (Labconco) equipped with a 12-port drying chamber.

The BioPACIFIC MIP's Additive Manufacturing Facility includes resources for rapid prototyping, advanced manufacturing, soft lithography, and 3D printing. The facility focuses on designing, building, and maintaining custom 3D printing platforms tailored to specific user-defined applications. Featuring state-of-the-art 3D printing processes, the facility routinely fabricates complex structures from novel bio-derived monomers, exhibiting a diverse range of mechanical, transport, optical, and chemical properties.

- Capabilities and Unique Aspects

-

To push the boundaries of 3D printing technology, the facility is equipped with a Carbon M2 printer and a Mono 3Z2 digital light processing (DLP) printer. Carbon's pioneering CLIP technology carefully balances the interaction of UV light, which triggers photopolymerization, and oxygen to inhibit polymerization. This process allows for continuous object construction from a pool of resin, achieving speeds 25 to 100 times faster than traditional 3D printing. The customized Mono 3Z2 DLP printer functions as a high-resolution visible light 3D printer, enabling the development of next-generation panchromatic photopolymer resins using LEDs in the visible spectrum (405 nm violet, 460 nm blue, 525 nm green, 615 nm red, and 730 nm near-infrared) with full control of the of the grayscale for each slice and the UV-Vis dose through adjustments in layer thickness, light intensity, exposure time, temperature, and environment. The facility also houses a dedicated system for the Solution Mask Liquid Lithography (SMaLL) process, capable of 3D printing unique multi-material objects with spatially-resolved mechanical and chemical properties; a Cellink BioX bioprinter for printing biological components, aqueous gels, and thermosets; and a Cellink LumenX DLP bioprinter.

Workflows include SMaLL, DLP, stereo lithography (SLA), material jetting (PolyJet), and fused deposition modeling (FDM). Users can leverage commercially available thermoplastics, silicones, colloidal suspensions, standard and stimuli-responsive gels, synthetic and biological resins, and even biological components (including living cells) to construct complex, high aspect ratio three-dimensional objects.

3D Print Technology Manufacturer Resolution (µm) Layer Thickness (µm) Print Speed Print Volume Excitation (nm) DLP SMaLL

(BioPACIFIC MIP)300 µm/min 470, 530 DLP Lumen X XY: 50

Z: 550 300 µm/min 65 x 40 x 50 mm

(130 mL)385 DLP Mono1 XY: 23 - 45 >25 420 µm/min 96 x 56 x 130 mm

(~700 mL)385 DLP Mono3 XY: 50 >25 300 µm/min 459, 520, 617 DLP Mono 3Z2 XY: 20 10 - 300 5,000 µm/min 38 x 22 x 153 mm

(128 mL)405, 460, 525, 615, 730 DLP Carbon M2 XY: 75

Z: 25 - 10025 - 100 SLA Formlabs Form 2 XY: 100 25, 50, 100 50 - 100 µm/min 145 x 145 x 175 mm

(3.7 L)405 FDM Stratasys F270 XY: 200 130 - 330 308 x 254 x 308 mm

(24 L)N.A. FDM Cellink BioX 20 20 0.6 – 3000 µL/min 128 x 85 x 37 mm

(0.4 L)N.A. PolyJet Stratasys Objet30 XY: 100 20 - 40 300 x 200 x 150 mm

(9 L)350, 400

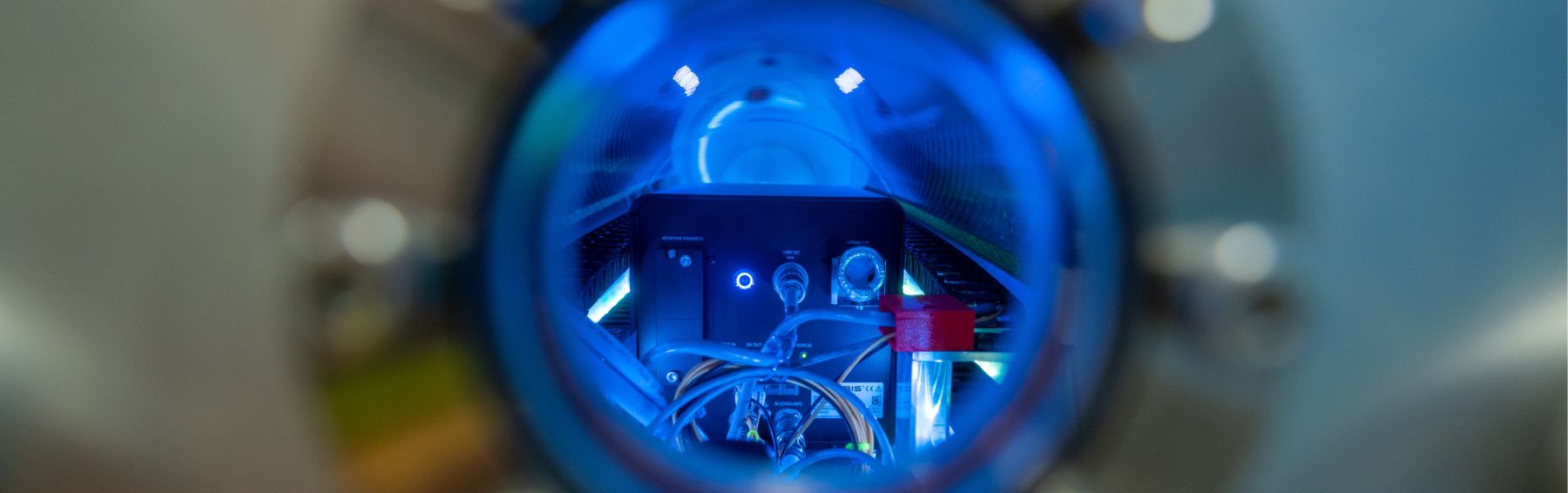

The BioPACIFIC MIP small-angle X-ray scattering (SAXS) Facility is a cutting-edge platform instrument for large length scale (~1nm-1000nm) nanostructure characterization of a broad range of bio-inspired materials. The instrument has been custom designed and constructed at UCSB to provide the most advanced capabilities for laboratory SAXS, using the brightest liquid metal jet laboratory X-ray source and the largest, most sensitive hybrid pixel photon counting 2D detector. In many key aspects, the performance of the BioPACIFIC MIP SAXS is comparable to a second-generation synchrotron SAXS, thus enabling laboratory based rapid-turnaround/high-throughput SAXS and WAXS data collection to meet the demand of the large research community at BioPACIFIC MIP.

- Capabilities and Unique Aspects

-

The key design capabilities of the BioPACIFIC MIP SAXS are:

- Multiple data collection modes to address a broad range of research needs, including SAXS, WAXS, GISAXS (grazing incidence SAXS), and GIWAXS.

- Tunable resolution and flux level depending on sample requirement.

- Custom designed Graphic User Interface optimized for high throughput workflow.

- Interface to a suite of environment stages (temperature, flow, etc.) for in-situ and time resolved studies.

- Modular architecture allows reconfiguration of the entire instrument when needed.

The many unique aspects of the BioPACIFIC MIP SAXS are a direct result of a modular architecture, which provides the flexibility to reconfigure the instrument to adapt to evolving research needs. Another important advantage of the custom designed platform is the ability to implement continual performance enhancements as new technologies become available. Most importantly, the open architecture enables the BioPACIFIC MIP research community opportunities to collaborate with the technical team to develop new SAXS and WAXS applications.

A typical user training session requires less than 2 hours (less with prior user experience in SAXS).

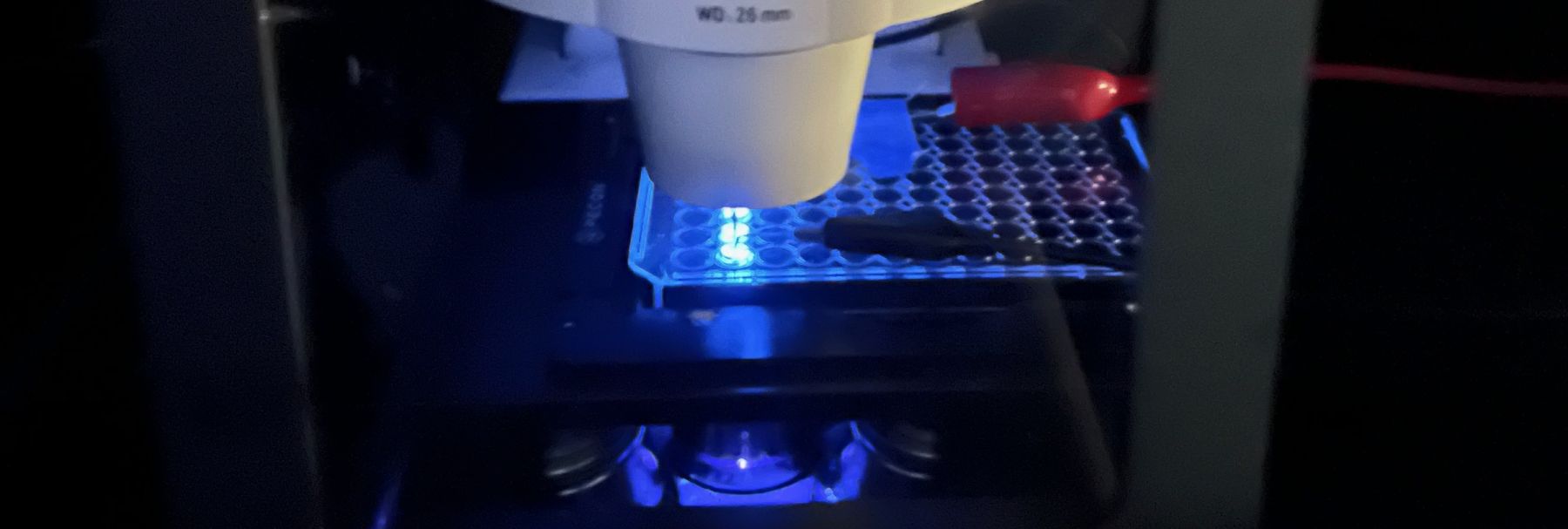

The High-Throughput Characterization Facility hosts and supports instrumentation for the structural, rheological, and mechanical characterization of materials, with a focus on high-throughput characterization. The available instrumentation includes an optical microscope with customized hardware and software, designed to serve as a first-in-class high-throughput automated microrheology tool for fluids and soft solids. Additionally, the facility is equipped with a high-throughput microindenter, which complements the microrheology tool by allowing for testing of materials much stiffer than possible with the microrheology tool alone. Furthermore, a versatile texture analyzer is available for linear and nonlinear mechanical measurements on solids.

- Capabilities and Unique Aspects

-

The high-throughput microrheometer consists of a Zeiss Axio Observer 7 inverted optical microscope system with fully motorized stages, objectives, and focus, as well as a multi-channel LED light source (Colibri 7), standard objectives, and filter sets for bright field, epifluorescence, and dark field imaging modes, automated hardware for optical sectioning (Apotome 2), and a 20 MP monochrome camera (Axiocam 702). The motorized stage is equipped with mount frames for standard well plates compatible with robotic sample preparation for high-throughput sample characterization. A light-tight enclosure equipped with an incubator provides stable temperature control of the microscope and samples. A temperature stage with custom microplates enables users to conduct degradation studies at elevated temperatures, up to 60 ºC, for several hours.

The high-throughput microindenter (Optics 11 Pavone) complements the microrheology tool, allowing for the mechanical characterization of stiffer materials (1 kPa to 1 GPa) across up to 192 different samples and includes microscopy capabilities. A wide range of cantilevers (0.02 - 4 N/m) with probes of varying radii (2 to 250 µm) are available to cover a broad spectrum of stiffnesses. An integrated surface-finding feature enables automated experimental workflows with commercially available microplates, eliminating the need for user supervision.

The texture analyzer consists of a Texture Technologies TA.XT-Plus Connect 650H Texture Analyzer equipped with a 5 kg (49 N) load cell. This system combines linear actuation and force monitoring with custom fixtures to perform a wide variety of mechanical characterization tests for soft solids, including indentation, puncture tests, uniaxial compression, uniaxial extension, notch tests, 90 Degree peel tests, sliding friction tests, and 3-point bend tests.

Workflows

A custom incubator chamber mounted onto the motorized stage of the Zeiss Observer 7 microscope enables in vitro studies of cell attachment and migration across multiple manufactured materials. The incubator is designed to maintain homeostatic conditions for mammalian cell culture: 37 ºC ± 0.1 ºC, 5 ± 0.01 % CO2, and >95 % RH. The incubator design modular and the chamber’s temperature, gases, gas flow rates, and relative humidity can be fully controlled to accommodate a variety of biological samples and maintain bacterial, fungal, or embryonic homeostatic conditions.

The high-throughput characterization platform can be used to achieve simultaneous, in situ mapping of time-evolving morphology and microrheology in phase separating complex fluids over a large compositional space. For example, this method was applied to a canonical example of polyelectrolyte complex (PEC) coacervation, where mixing of oppositely charged species leads to liquid–liquid phase separation into distinct solute-dense and dilute phases (https://doi.org/10.1039/d1sm01763b). Morphology and rheology were measured simultaneously and kinetically after mixing to track the progression of phase separation. The relationships between composition and viscosity were extracted from the large datasets, predicting phase diagram boundaries that were independently validated by traditional thermogravimetric analysis (TGA), resulting in significant time and cost reductions in constructing a coacervate phase diagram.

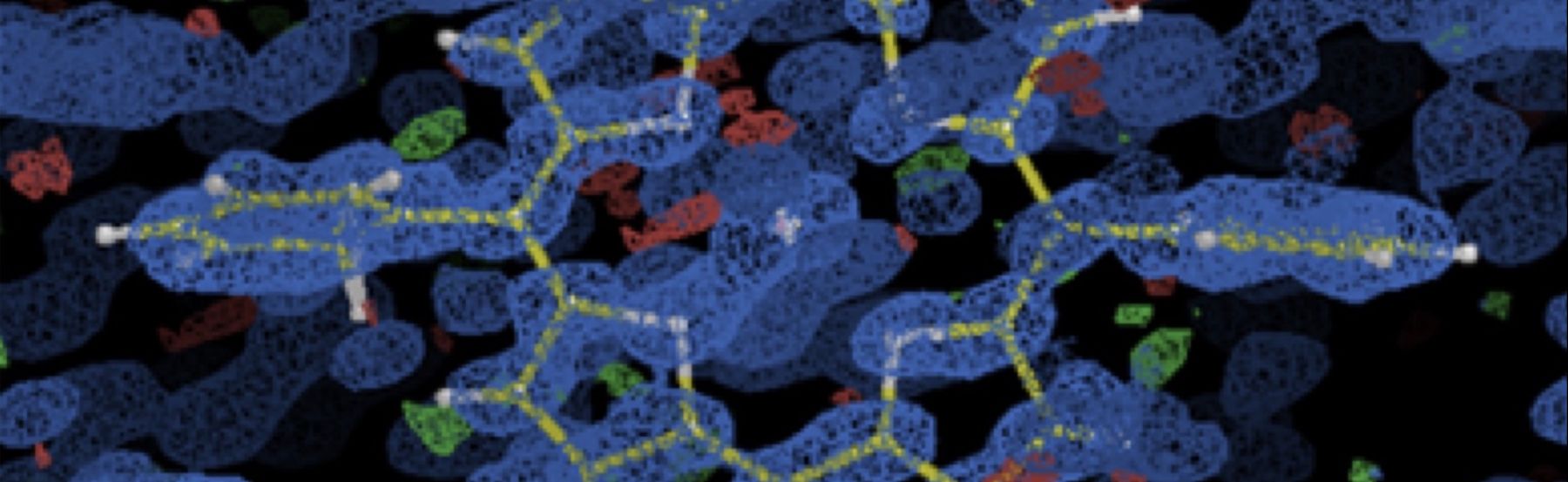

The BioPACIFIC MIP facility for High-Throughput Transmission Electron Microscopy (HTTEM) endeavors to further develop the nascent technology of polymer (along with small molecule and protein) characterization using low-dose imaging, electron diffraction, diffraction tomography, and 4 dimensional scanning transmission electron microscopy (4DSTEM). The facility includes associated processes for sample preparation, data acquisition, and image analysis. The facility provides access to a state-of-the-art electron microscopy platform that enables fast and reliable structure determination of a variety of structures using microED, along with cutting edge phase imaging and 4DSTEM strain mapping.

- Capabilities and Unique Aspects

-

The cornerstone technology for this facility, the ThermoFisher Scientific (TFS) Spectra 300 C-TWIN X-CFEG (Spectra 300C), is a state-of-the-art transmission electron microscope (TEM) specially designed for optimized electron diffraction. This first of its kind instrument takes the best tools from the cryogenic electron microscopy workflow and combines them with the array of tools developed for materials science imaging. This blend produces a microscope that can operate in many roles, focusing on diffraction and imaging of dose sensitive materials. The Spectra 300C’s electron source is an X-CFEG (cold field emission gun) that makes the beam of electrons more wave-like (at synchrotron levels of brightness). In addition, the microscope is equipped with a three-condenser lens system, and a side entry stage for cryo-transfer double tilt operation during microED and cryo-4DSTEM experiments.

The Spectra 300C is equipped with a suite of detectors for both TEM and STEM. TEM mode, where a parallel beam of electrons illuminates the sample, uses the Ceta-D CMOS speed upgraded camera for high-resolution (sub-1Å) continuous rotation microED and scanning nanobeam electron-diffraction tomography (nanoEDT) data on dose-sensitive samples. A Falcon 3 camera is installed to provide single particle analysis imaging of non-crystalline samples. STEM mode, where a focused electron beam rasters across the sample, uses a Panther STEM detector system with differential phase contrast (DPC), integrated DPC for phase detector (iDPC), and OptiSTEM+ for automated STEM alignments.

The microscope also offers semi-automated high-resolution STEM imaging performance at ultra-low fluences of beta radiation (1-100 electrons per angstrom squared) and energies from 30-300kV (alignments at 30, 60, 80, 120, 150, 200, and 300 kV). The X-CFEG allows for two Angstrom direct imaging resolution. The cryogenic capabilities of the Spectra 300C (cryobox and CTWIN pole piece) provide a reduction of ice buildup on the sample. This enables long working times at cryogenic conditions; conditions that are needed to provide protection to the most dose-sensitive samples.

Watch: BioPACIFIC MIP Laboratory Tour

Video index:

- 00:17 UCLA MicroED Facility

- 11:14 UCSB Synthetic Chemistry Facility and Microrheology

- 20:44 UCSB X-Ray Scattering Facility

- 26:49 UCSB Additive Manufacturing Facility

- 31:22 UCLA Living Biofoundry Facility