Modular Synthesis and Patterning of High-Stiffness Networks by Postpolymerization Functionalization with Iron−Catechol Complexes

Versatile synthetic procedure for preparing mechanically tunable materials using a two-step process of dual cross-linked networks.

PIs and Institution

Matthew Helgeson, Rachel Segalman, Megan Valentine, and Craig Hawker (UCSB)

Achievement

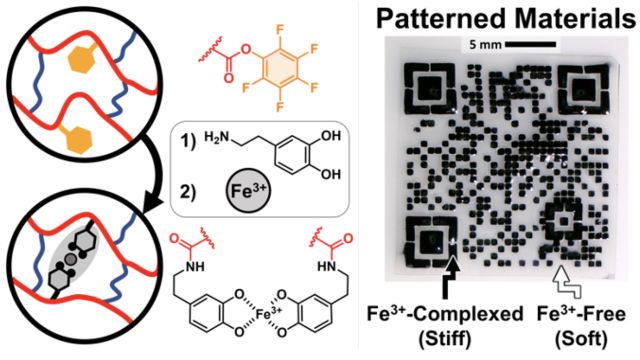

This work presents a versatile synthetic procedure for preparing mechanically tunable materials using a two-step process of dual cross-linked networks. The first step involves free radical cross-linking of vinyl monomers to create an initial functionalized network. The second step involves post-modification using active ester substitution to create catechol-grafted networks, which can be mechanically reinforced with Fe3+−catechol cross-links through solution processing. By tuning the ratio of each building block, these networks can exhibit a wide range of properties (Young’s moduli up to ∼245 MPa), well beyond the values achieved through purely covalent cross-linking. This stepwise approach demonstrates how bioinspired molecular patterns can be utilized to design complex materials with hierarchical strengthening motifs that exhibit improved properties for soft robotic and bioinspired composite applications.

Importance of the Achievement

This combination of a covalent network with a percolating metal−ligand cluster network represents a promising approach to creating stiff, strong, and tough loadbearing polymer networks. Furthermore, soft lithography solution masking techniques can leverage controlled iron diffusion into catechol networks to spatially pattern 3D films with hard−soft regions with submillimeter feature sizes and to prepare novel gradient systems. The user-friendly nature of this two-step strategy along with the versatility of radical cross-linking systems and the wide availability of starting materials could also enable the preparation of patterned materials for soft robotics tissue engineering scaffolds, and high-strength, functional 3D printed materials.

Unique Features of BioPACIFIC MIP that Enabled this Achievement

This work used the BioPACIFIC MIP TA.XT benchtop tensile tester for the mechanical testing of polymer film moduli, which is crucial for determination of film stiffness and confirmation of microstructural impact on macroscopic properties.