Modular 3D-Printed Polymer Networks

A strategy for making a new class of additive manufacturing resins has been developed.

PIs and Institution

Christopher Bates, Craig Hawker, and Javier Read de Alaniz (UCSB)

Achievement

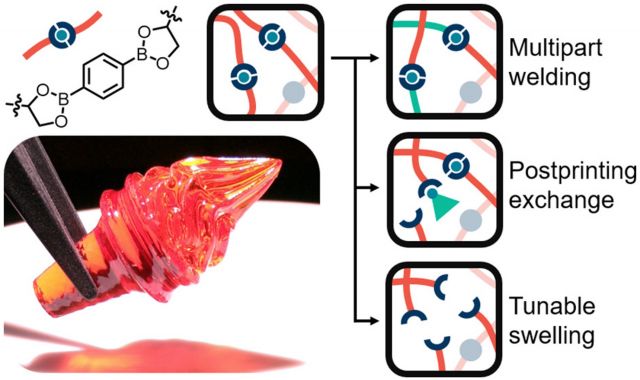

A vat photopolymerizable 3-D printing resin that consists of both permanent (diallyl phthalate) and exchangeable (boronic ester) crosslinks that increase the sustainability of the printed material, was developed. The adaptable polymer network of the resin, essentially allows the material to be printable, repairable and recyclable. Objects printed with this hybrid dynamic/static resin exhibit a balance of structural stability (due to the diallyl phthalate bonds) as well as rapid exchange (due to the dynamic nature of boronic ester bonds), allowing for tunable swelling, multipart welding and room temperature post-printing chemical functionalization.

Importance of the Achievement

Traditional additive manufacturing thermosets have limited material lifecycles due to the non-exchangeable chemical crosslinks that affix polymer chains together. As a result, these polymer networks are usually landfilled or incinerated. By incorporating a fraction of exchangeable covalent crosslinks into a resin, the resulting materials can undergo a variety of post-printing modifications, which extend the lifecycle of the parent network and provide upcycling avenues. This is an important sustainability benefit, considering the rapidly increasing quantity of 3D-printed material being produced every year.

Unique Features of BioPACIFIC MIP that Enabled this Achievement

BioPACIFIC MIP provided the one-of-a-kind Solution Mask Liquid Lithography (SMaLL) 3D-printing system, developed in-house, as well as the Innovation Workshop, that were used for the 3D printing in this project . Technical assistance from BioPACIFIC MIP staff David Bothman was instrumental to this research.