New first-of-its-kind Electron Diffraction Tomography (MicroED) microscope available at BioPACIFIC MIP facilities

The BioPACIFIC MIP team has completed the construction and installation of a state-of-the-art transmission electron microscope (TEM) and has made the instrument available to users.

PIs and Institution

BioPACIFIC MIP at UCLA

Achievement

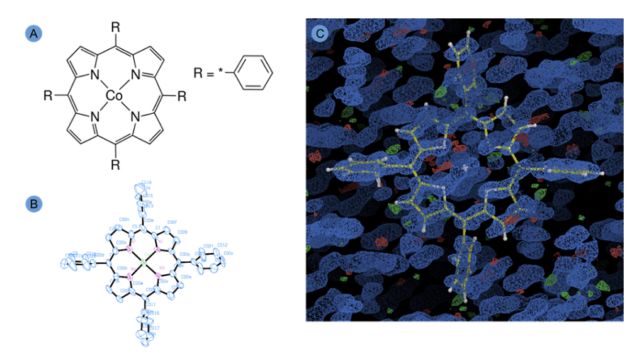

The BioPACIFIC MIP team has completed the construction and installation of a state-of-the-art transmission electron microscope (TEM) and has made the instrument available to users. The first-of-its-kind microscope is optimized for high throughput determination of atomic structure using micro-electron diffraction (microED), configured specifically for BioPACIFIC MIP’s needs. It features the first 3rd-generation Spectra-class microscope to feature a large gap electromagnetic pole piece, an anti-ice contamination mechanism, high-speed high-tension switching capabilities, and a next generation high-brightness field emission electron source. By acquiring diffraction patterns at different angles through a continuous rotation, and then processing through software analysis tools, the 3D structure of a molecule can be determined. Scientists can use the microscope to determine the crystalline structures of proteins and other small molecules even in very small sample quantities or in very small crystals.

Importance of the Achievement

MicroED can fill an important gap in structural biology and chemistry analysis. The current structural characterization techniques fail to elucidate the structure when a molecule cannot form large crystals, or in cases of very small sample volumes. The new MicroED instrument can push the boundaries of structural characterization in these cases, and in conjunction with BioPACIFIC MIP’s high-throughput synthetic capabilities, a large array of molecules can be synthesized and structurally characterized, accelerating the informed discovery of new materials. Moreover, the data can be acquired in minutes (as compared to days in the case of direct imaging or x-ray synchrotron use) and processed within hours. The time to determine a structure is therefore shortened, closing the MGI feedback loop of Design-Build-Test-Learn faster.