Controlled Synthesis of a Homopolymer Network Using a Well-Defined Single-Component Diels–Alder Cyclopentadiene Monomer

An approach for the controlled synthesis of a homopolymer network using a well-defined cyclopentadiene (Cp) monomer.

PIs and Institution

Javier Read de Alaniz (UCSB)

Achievement

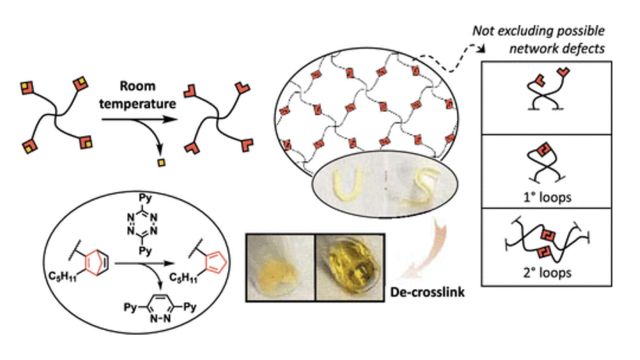

This work provides an unprecedented and feasible approach for the controlled synthesis of a homopolymer network using a well-defined cyclopentadiene (Cp) monomer, which has been historically challenging due to its high reactivity and tendency to dimerize. The authors present a strategy not only to synthesize, isolate, and homopolymerize a well-defined tetracyclopentadiene monomer but also to de-cross-link the network homopolymer. Investigation of the mechanical properties, including creep−recovery, shape memory, and tensile behaviors showed a tough and elastic material, in contrast to prior Cp-based homopolymer networks. The polymer’s near-room-temperature glass transition temperature (Tg) along with its toughness and elasticity make it an excellent candidate for shape memory and degradable thermoset applications.

Importance of the Achievement

Despite a long history and compelling chemistry, there have only been two attempts to homopolymerize similar monomers since 1926, due to their formidably uncontrolled reactivity. This breakthrough work provides a new approach to synthesizing and controlling the polymerization of Cp monomers in mild conditions, paving the way to the development of new responsive materials. The properties of the resulting polymer, including its near-room-temperature Tg and elastomeric properties, are intriguing and promising for various applications, such as shape memory polymers and degradable thermosets. Additionally, the emergent properties and accessible methodology can inspire further research and development of advanced materials that will take advantage of its homogeneous bulk polymerization, better-defined cross-link architecture, compelling shape flexibility, and degradability.

Unique Features of BioPACIFIC MIP that Enabled this Achievement

This work used the BioPACIFIC MIP TA.XT benchtop tensile tester for the mechanical testing of polymer film moduli and strain, which is crucial for determination of film toughness and confirmation of microstructural impact on macroscopic properties. BioPACIFIC MIP also provided financial support for materials and researchers through the Fellows program.